AI Is Transforming Jet Engines at GE Aerospace

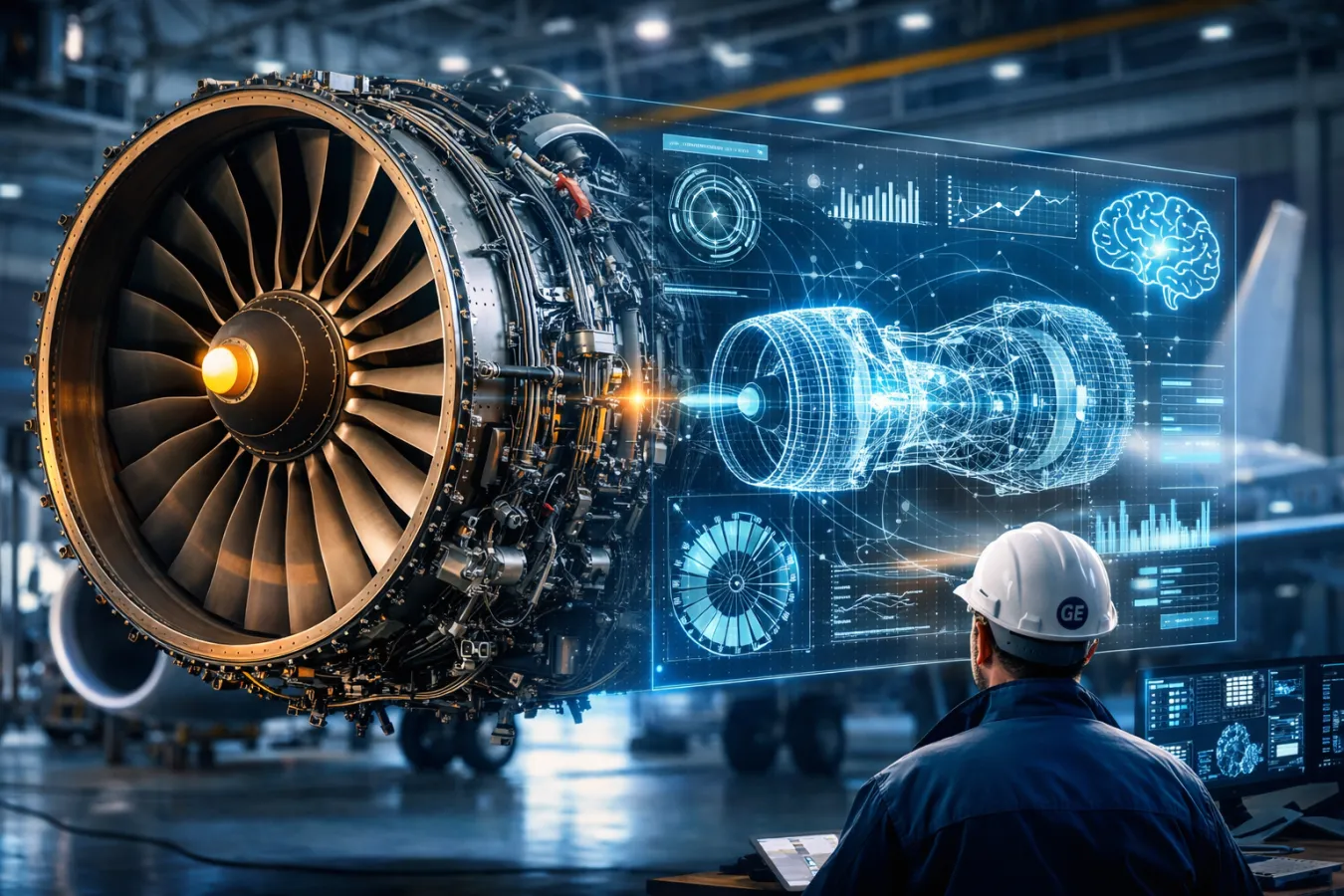

Artificial intelligence is no longer a future concept in

aviation — it is already transforming how jet engines are designed, built,

inspected and maintained. Leading this shift is GE Aerospace, one of

the world’s most influential aerospace engineering companies.

With decades of experience in jet propulsion and more than 1,000

AI-related patents, GE Aerospace is using artificial intelligence to

improve engine reliability, reduce aircraft downtime and redefine the future of

aviation engineering.

In this article, we explain how AI is changing jet

engines, what GE Aerospace leaders have revealed at major conferences and

why this innovation matters for the global aerospace industry.

How AI Is Changing Jet Engines at

GE Aerospace

GE Aerospace has embedded artificial intelligence across the

entire jet engine lifecycle. From early-stage design to real-time

monitoring, AI systems now help engineers analyze massive volumes of engine

data that would be impossible to process manually.

By using machine learning, digital twins and predictive

analytics, GE Aerospace can detect engine anomalies earlier, predict

maintenance needs and improve long-term engine performance. This data-driven

approach allows aircraft to stay in service longer while maintaining high

safety standards.

AI-Powered Inspection and

Predictive Maintenance

One of the biggest breakthroughs is AI-based engine

inspection. According to GE Aerospace leadership, AI tools have increased fault

detection accuracy by around 45% while reducing inspection time by nearly 50%.

This improvement is critical for airlines and maintenance

teams worldwide. Faster inspections mean fewer delays, lower maintenance costs

and improved fleet availability. Predictive maintenance also allows airlines to

fix problems before failures occur, improving both safety and

efficiency.

Generative AI and Smarter

Aircraft Maintenance

GE Aerospace is also adopting generative AI in

collaboration with technology partners like Microsoft and Accenture. These

systems can analyze complex maintenance records, service histories and

technical documents in minutes instead of weeks.

At global aviation conferences, GE Aerospace demonstrated

how generative AI helps airlines quickly access maintenance insights, make

better operational decisions and reduce aircraft ground time. This represents a

major step forward for AI-driven aviation operations.

AI in Jet Engine Design and

Engineering Innovation

Artificial intelligence is not only improving maintenance —

it is transforming how jet engines are designed.

At GE Aerospace research and development centers, AI models

work alongside physics-based simulations to explore thousands of design

variations rapidly. Engineers can now optimize engines for fuel efficiency,

durability and sustainability faster than ever before.

AI also enables the creation of digital twins —

virtual copies of jet engines that mirror real-world performance. These digital

replicas help engineers monitor engines continuously and anticipate future

issues with higher accuracy.

GE Aerospace’s AI Strategy and

Long-Term Vision

To scale innovation, GE Aerospace has deployed AI tools

across its workforce. Its internal AI platform allows engineers and technicians

to automate repetitive tasks, analyze data faster and focus on high-value

problem solving.

This company-wide adoption highlights how central artificial

intelligence is to GE Aerospace’s future of flight strategy, where human

expertise and intelligent systems work together to enhance aviation safety and

performance.

Why AI in Jet Engines Matters for

the Aerospace Industry

Artificial intelligence is now a core technology in

aerospace engineering, not an optional upgrade. GE Aerospace’s leadership

in AI reflects broader changes across the aviation sector:

- Faster

inspections increase aircraft availability

- Predictive

analytics reduce operational costs

- AI-driven

design speeds up engine development

- Generative

AI improves decision-making across fleets

As global demand for efficient and sustainable air travel

grows, AI-powered jet engines will play a critical role in shaping the future

of aviation.

The Future of Aerospace

Engineering Starts Now

GE Aerospace’s use of artificial intelligence shows how

advanced engineering, data science and aviation expertise are merging. By

embedding AI into jet engine innovation, GE Aerospace is setting new standards

for performance, safety and reliability across the global aerospace industry.

The future of aerospace engineering will not replace humans

— it will empower them with intelligent tools that make flight safer,

smarter and more efficient.